Vibratory Bowl Feeders

High-performance component feeding solutions engineered for maximum efficiency and reliability in industrial manufacturing processes

Powerful electromagnetic drive system

Welcome to your ultimate destination for efficient, reliable, and customisable vibratory bowl feeders. In today’s fast-paced manufacturing environment, optimising production processes is essential. Our vibratory bowl feeders, with their unique selling points of increased efficiency, customisation, durability, and versatility, are engineered to enhance your material handling and feeding operations, helping you achieve maximum productivity with minimal downtime.

What Are Vibratory Bowl Feeders?

Welcome to your ultimate destination for efficient, reliable, and customisable vibratory bowl feeders. In today’s fast-paced manufacturing environment, optimising production processes is essential. Our vibratory bowl feeders, with their unique selling points of increased efficiency, customisation, durability, and versatility, are engineered to enhance your material handling and feeding operations, helping you achieve maximum productivity with minimal downtime.

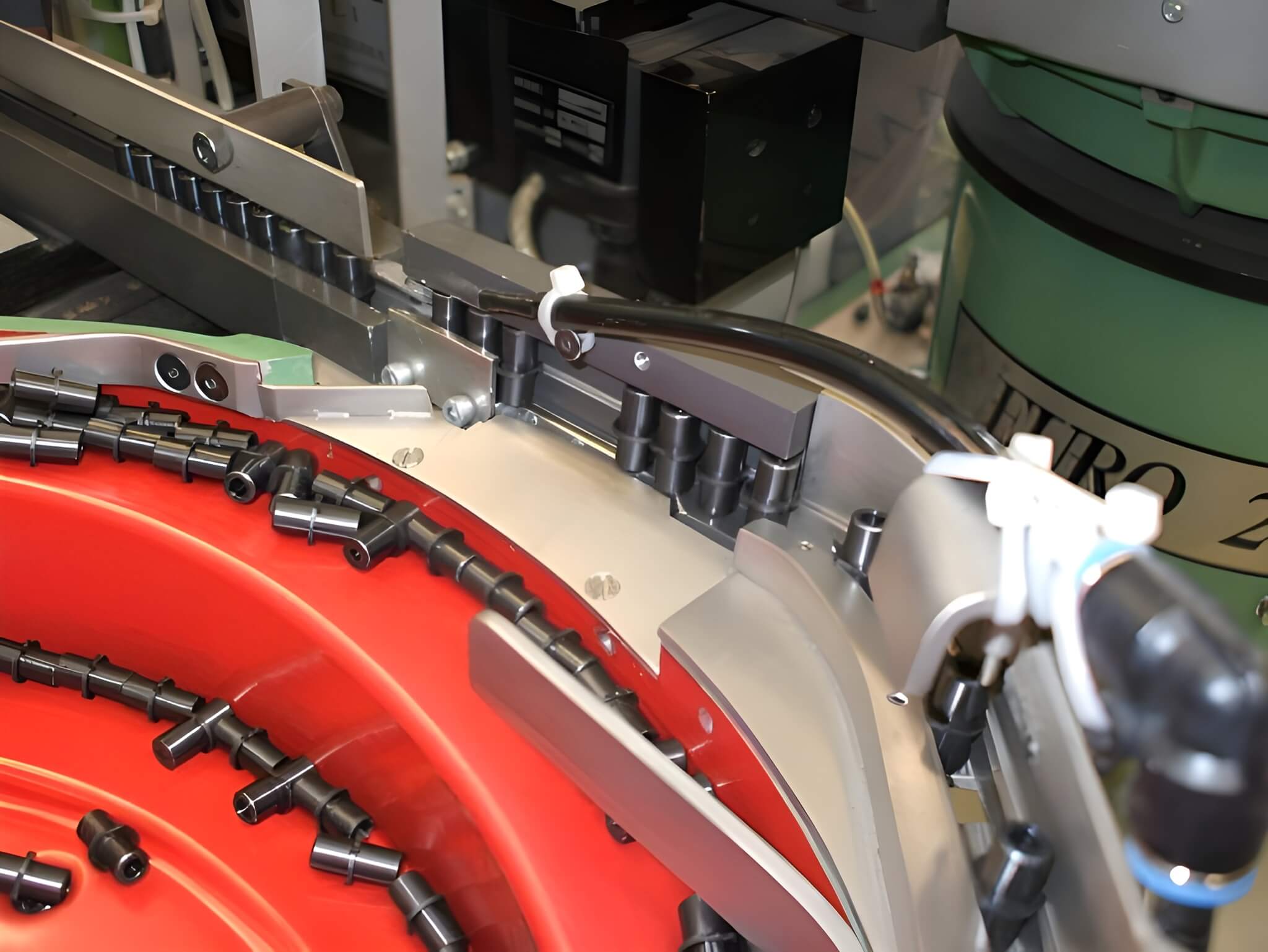

How Our Vibratory Bowl Feeders Work

The operation of a vibratory bowl feeder is straightforward yet highly effective. Material is placed into the bowl, which then vibrates, causing the parts to move. The bowl’s configuration promotes the separation and alignment of the pieces, funnelling them into a single line for easy retrieval. The feeders’ built-in sensors can be integrated to detect and sort specific items, further enhancing efficiency.

Key Benefits of Using Vibratory Bowl Feeders

- Increased Efficiency: By automating feeding, vibratory bowl feeders significantly reduce the time required to prepare materials for assembly. This allows your team to focus on value-added tasks rather than repetitive feeding.

- Customisation: Our vibratory bowl feeders can be tailored to meet the unique requirements of your operation. Whether you’re working with small electronic components or larger automotive parts, we offer customisable solutions designed to improve functionality and efficiency.

- Durability and Reliability: Built from high-quality materials, our vibratory bowl feeders are designed for longevity and can withstand the rigours of continuous use. With a robust design, you can trust your system will remain operational and deliver consistent performance over time.

- Versatility: Our vibratory bowl feeders are not limited to a single industry. They are suitable for a wide range of industries, including pharmaceuticals, food production, electronics, and manufacturing. This versatility makes them the go-to solution for a wide range of applications, enabling them to be adapted to meet your specific requirements regardless of your industry.

- Easy Maintenance: Our feeders are designed for simplicity, requiring minimal maintenance. This feature not only reduces repair costs but also ensures your operations continue without unnecessary interruptions, giving you peace of mind about the long-term reliability of our product.

Advanced feeding solutions

Optimise production with intelligent automation solutions

Rapid component transport

Achieve up to 22 meters per minute feed rates

Flexible bowl configurations

Range from 80mm to

1000mm diameter

Robust construction options

Stainless steel, cast aluminium, and polyurethane lining available

Vibratory Bowl Feeders

Technical

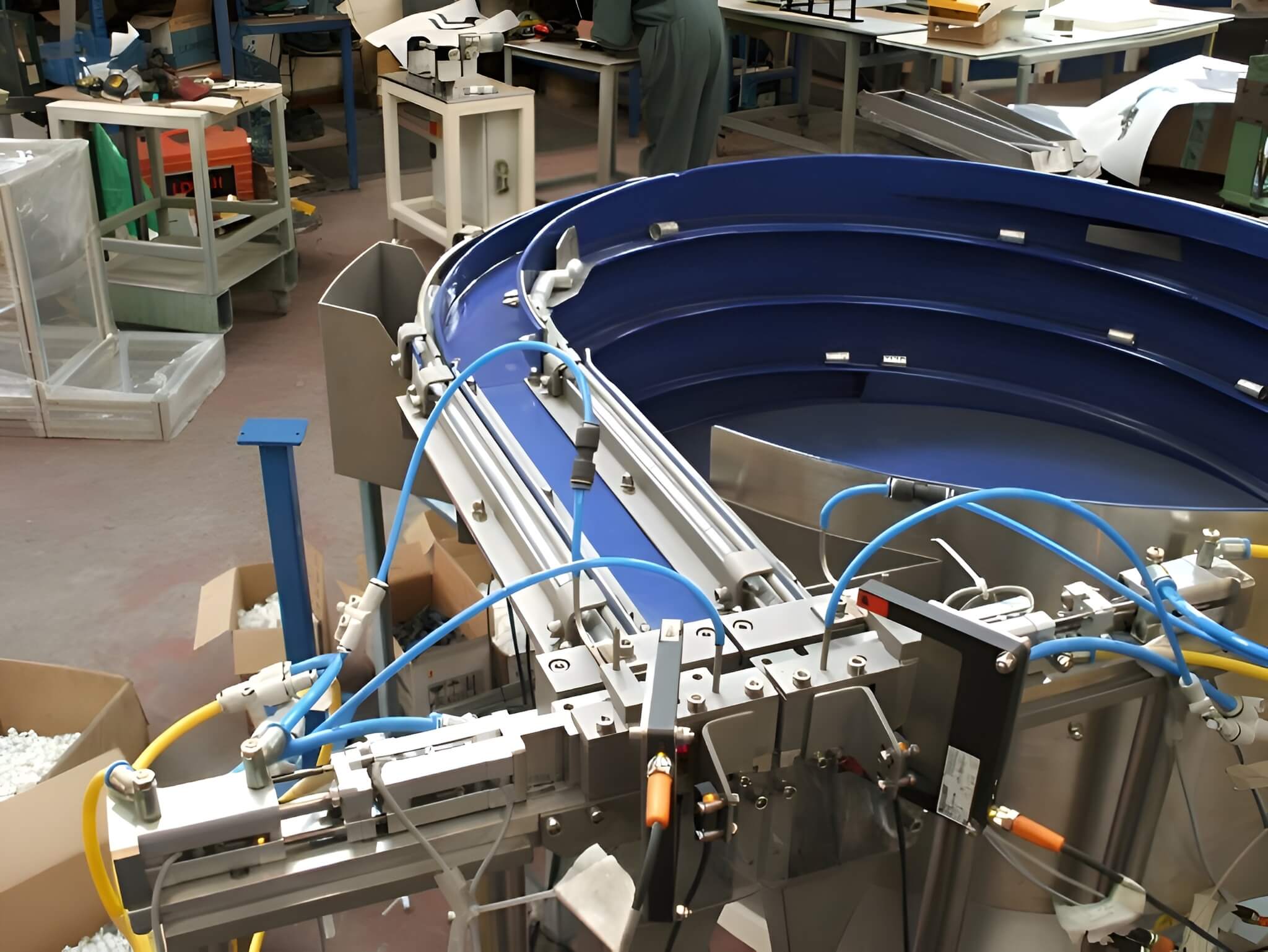

Vibratory Bowl Feeders are powered by a totally encapsulated electromagnetic coil, driving through a series of laminated fibreglass leaf springs. The solid base vibrates in resonance with the top platform and bowl, generating high directional drive.

Speeds of up to 22 metres per minute can be achieved, enabling high component feed rates.

A standard range of bowl sizes is available from 80mm to 1000mm in diameter, and they can be supplied and manufactured in mild or stainless steel, or cast aluminium, with the option of an internal polyurethane lining.

Vibratory bowl feeders can be supplied with plain feed flights or fully tooled for the selection and orientation of specific components and applications.

Each vibratory bowl feeder is supplied with a variable-speed controller and is suitable for operation from a standard single-phase electrical supply.

Vibratory bowl feeders can be configured to run in conjunction with Belt elevators for bulk supply and/or Linear Feeders for buffer and storage.

Why choose Alphamation

Delivering precision engineering solutions for complex manufacturing challenges

Exceptional Support and Expertise

At Alphamation, we pride ourselves on providing not only superior vibratory bowl feeders but also unmatched customer support. Our team of experts is dedicated to helping you choose the right solution for your needs and ensuring seamless integration into your production line. From initial consultation to installation and ongoing support, we are here to assist every step of the way.

Get Started Today!

Are you ready to elevate your production efficiency with our cutting-edge vibratory bowl feeders? Don’t let inefficient processes slow down your operations any longer.

Contact us today for a free consultation and let our experts help you find the perfect feeding solution tailored to your specific needs! Transform your manufacturing processes and watch your productivity soar with Alphamation!

Speed

High-velocity component handling with minimal production interruption.

Precision

Accurate positioning and orientation of components with microscopic tolerances.

Flexibility

Adaptable systems designed to integrate seamlessly with diverse manufacturing workflows.

“Alphamation’s automation solutions have dramatically improved our production efficiency and reduced component handling errors.”

James Thompson

Production director, Automotive Manufacturing Ltdr dapibus leo.

“Alphamation’s automation solutions have dramatically improved our production efficiency and reduced component handling errors.”

James Thompson

Production director, Automotive Manufacturing Ltdr dapibus leo.

Companies We’ve Worked With

Ready to optimise your workflow

Connect with our automation experts to discover precision feeding solutions tailored to your manufacturing challenges.

Contact Us

Our team is ready to provide technical

support and consultation

info@alphamation.co.uk

Phone

01384 412255

Fax

01384 413191

Office

9 Bassett Road

Cradley, Halesowen

West Midlands, England

B63 2RE